Medina House

Description

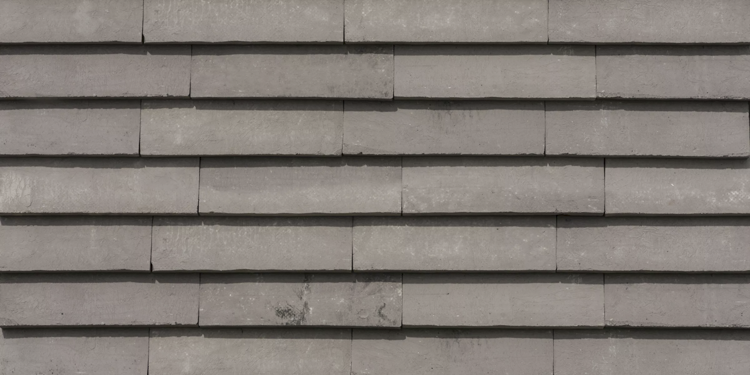

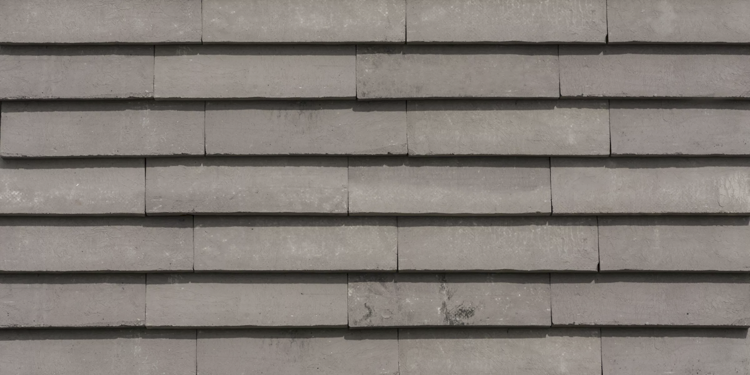

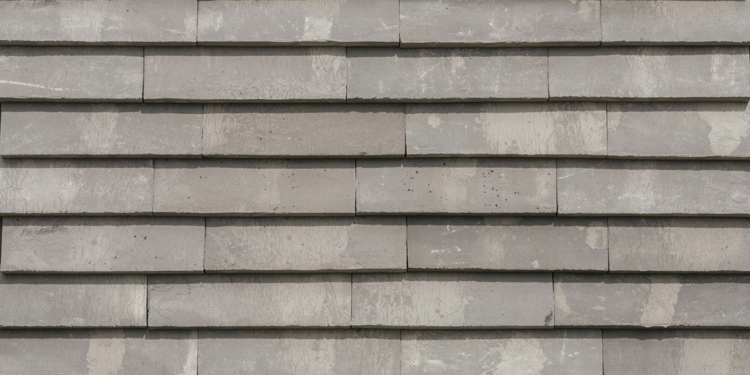

Medina House is a highky bespoke, environmentally conscious family home on Brighton’s historic Hove beachfront, designed on the site of a former Victorian women’s bathhouse. Referencinf the original structure’s character – including its Dutch gables and arched openings – the new home reinterprets its form with refined modern detailing. A sequence of vaulted soaces and split levels create spatial richness across three storeys, while the architecture remains rooted in the local context though its use of chalky-white Petersen Kolumba bricks – echoing the stratified Sussex coastline and responding to shifting coastal light.

Externally, the home features loadbearing white Petersen Kolumba bricks with handmade textures, deep reveals, and culptural arches. The facafe includes a complex coubly-curved precast concrete arch above the main feature window = achieced through 3D modelling and brick slip application – along with a freestanding 7m-high garden wall with opaque glazing and non-loadbearing arches. The project’s fabric-first design also prioritises sustainability, integtrating a grounf-source heat pump, natural ventilation, and saltwater-resistent timber joinery to withstand the marine environment.

Requirements

EBM was deeply involved in delivering the architectural vision for Medina House, providing expertise on brick bonding, bespoke specials, and installation strategies for the complex curved and tapering elements. We collaborated with Pilbrow & Partners on the design of the precast arch and proposed an in-situ method for constructingthe concave feature window. Where required, we pushed the boundaries of manufacturing, inclusiding suppying ultra-thin 600mm bricks and precision-cutting them down to 10mm to achieve the projects’s refined detailing. EBM’s deep product knowledge and manufacturing insight ensure feasibility, precision, and material integrity throughout – a level of service few others can provide.

Location

Key challenges

1/ Designing and producing ultra-thin bespoke brick specials

2/ Coordinating with structural and architectural teams to execute complex concave arches

3/ Delivering handcrafted finished products while maintaining structural and aesthetic precision

4/ Supporting the creation of precast concrete lintel with integrated brick slip application

Highlights & Achievements

- — Delivered one of the most technically demanding facades in the region

- — Reimagined a historic site with handcrafted architectural sensitivity

- — Achieved exceptional material expression through technical innovation and collaboration